3D printing technology has revolutionized prototyping and manufacturing, but like any technology, it can encounter issues. A common problem faced by 3D printer users is the printer stopping mid-print with a ‘filament runout’ alert, even when there’s still filament present. This can be frustrating, especially if your printer is relatively new. Let’s explore the possible causes and solutions for this issue.

Understanding the Filament Runout Sensor

Most modern 3D printers are equipped with a filament runout sensor. This sensor is designed to pause the print if it detects that the filament has run out, preventing incomplete prints and saving time and resources. However, if this sensor malfunctions or is triggered incorrectly, it can stop the print unnecessarily.

Common Causes for False Alerts

Sensor Misalignment or Damage

If the sensor is misaligned or damaged, it may not detect the presence of the filament correctly. Check the alignment and condition of the sensor.

Filament Diameter Inconsistencies

Some filaments have slight variations in diameter along their length. If the filament becomes too thin at a certain point, the sensor might mistakenly interpret this as the filament running out.

Dust or Debris

Accumulation of dust or debris in the sensor area can obstruct its ability to detect filament. Cleaning the sensor and its surroundings can resolve this issue.

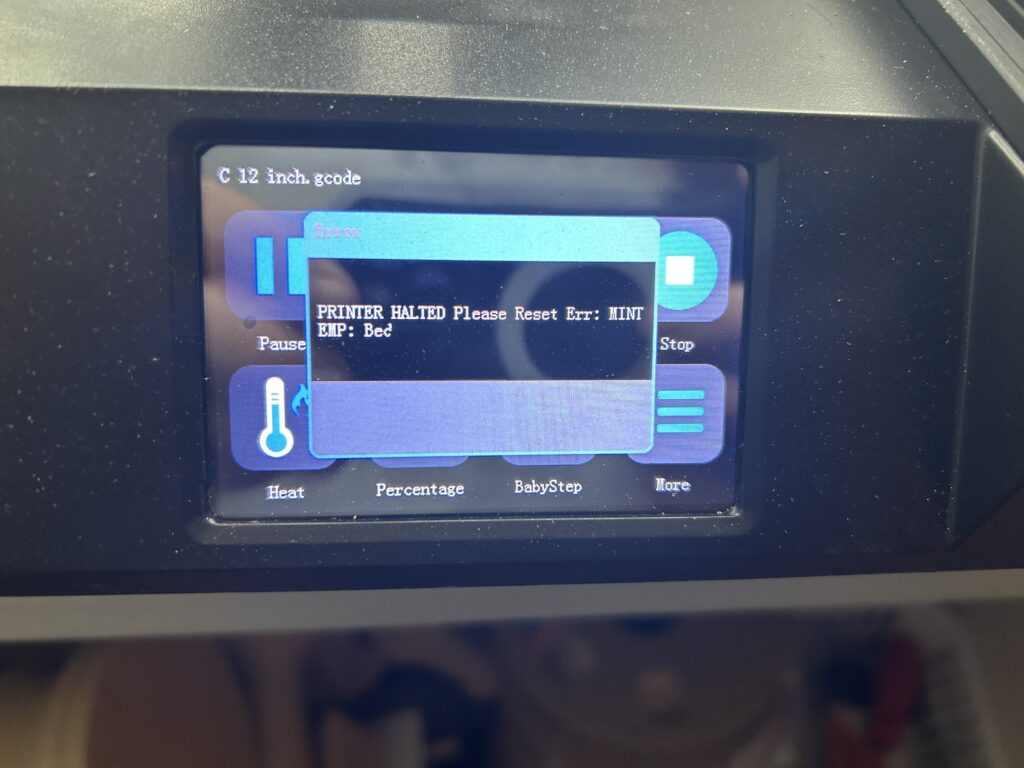

Firmware Glitches

Sometimes, the problem could be related to the printer’s firmware. Glitches or bugs in the software can cause false runout alerts.

Electrical Interference

In rare cases, electrical interference or a loose connection can cause the sensor to malfunction. Ensure all connections are secure and check for sources of interference.

Solutions to Fix the Issue

Adjust or Replace the Sensor

If the sensor is misaligned, adjust it according to the manufacturer’s instructions. If it’s damaged, it may need to be replaced.

Use High-Quality Filament

Opt for high-quality filament with consistent diameter to avoid triggering the sensor inaccurately.

Regular Maintenance

Regularly clean your printer and sensor area to prevent dust and debris buildup.

Update Firmware

Check for firmware updates for your printer. Manufacturers often release updates to fix known bugs and improve performance.

Check Electrical Connections

Ensure all connections related to the sensor are secure. If you’re comfortable with electronics, you can check the wiring and connections for any issues.

A false filament runout alert can be a nuisance, but it’s usually fixable with some troubleshooting. By understanding the potential causes and exploring these solutions, you can get your 3D printer back to functioning correctly. Remember, regular maintenance and using quality materials can prevent many common 3D printing issues. If the problem persists, consulting the manufacturer or a professional technician is advisable.

Q: What should I do if my 3D prints are not sticking to the bed? A: First, ensure that the print bed is level and clean. Adjust the bed temperature according to the filament type. Using adhesives like hairspray or glue stick on the bed can also improve adhesion. If the issue persists, consider using a raft or brim in your print settings.

Q: Why is my 3D printer making unusually loud noises during printing? A: Loud noises can be due to loose components or lack of lubrication. Check for any loose belts or screws and tighten them. Also, lubricate the moving parts of the printer, such as rods and bearings, with appropriate lubricants.

Q: How can I prevent warping in my 3D prints? A: Warping usually occurs due to uneven cooling. Ensure that the printing environment is free from drafts and sudden temperature changes. Using a heated bed can also significantly reduce warping, especially for materials like ABS.

Q: My 3D printer is extruding too much or too little filament. What should I do? A: This could be due to incorrect extruder calibration. Calibrate the extruder to ensure it’s pushing the right amount of filament. Also, check the filament diameter settings in your slicing software to ensure they match your filament.

Q: The filament keeps clogging in the nozzle. How can I fix this? A: Clogging can occur due to a dirty nozzle or printing at too low a temperature. Try cleaning the nozzle. If the problem persists, increase the printing temperature in small increments. Also, ensure you’re using high-quality filament to avoid impurities that can cause clogs.

3D printing, while innovative and rewarding, comes with its set of challenges. Addressing common issues like bed adhesion, noise, warping, extrusion problems, and nozzle clogging can significantly improve your printing experience. Regular maintenance, proper calibration, and using quality materials are key to successful 3D printing. For more detailed guides and troubleshooting tips, visit the rest of our website Device Junkies for a range of articles on 3D printing and technology.

As an Amazon Associate we earn from qualifying purchases through some links in our articles.